MAC MIX ARABIA COMPANY LIMITED designs and manufactures industrial-grade polymer mixer plants that support bitumen modification asphalt enhancement and polymer blending operations across Saudi Arabia and the GCC.

These plants are engineered to improve road quality by enhancing flexibility stability and resistance against rutting and temperature variations.

Built with advanced heating control precise dosing systems and robust mixing chambers, our polymer mixer plants ensure consistent product quality with minimal operator intervention.

FEATURES

Features

- Uniform Polymer Dispersion Advanced high-shear mixing ensures complete and uniform polymer distribution within bitumen

- Temperature-Controlled Processing Automatic temperature regulation prevents overheating and polymer degradation during mixing

- Energy Efficient Operation Optimized burner and heating coil design minimizes fuel consumption and heat loss

- Customizable Capacity Options Modular plant configurations to suit small medium or large-scale asphalt production requirements

- Low Maintenance Design Easy access layout and wear-resistant components reduce downtime and simplify servicing

- Heavy-Duty Construction Industrial-grade structure built to withstand continuous operation in harsh environments

- Automated Control System PLC-based control with real-time temperature flow and mixing ratio monitoring ensures accuracy and repeatability

- Enhanced Road Performance Bitumen modified using this system delivers higher resistance to cracking deformation and weathering

PRODUCT Introducion

Truck Weighing Bridge

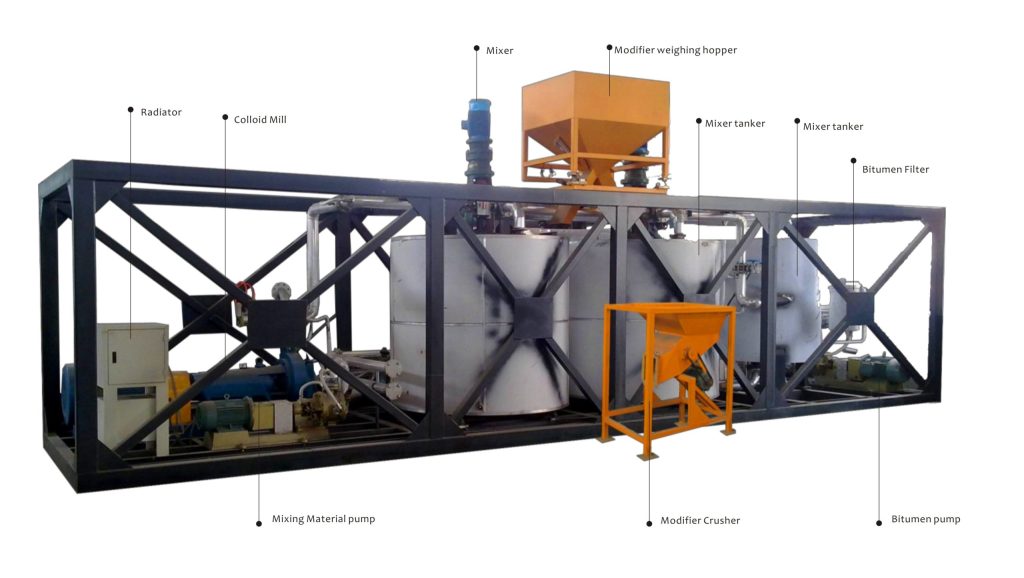

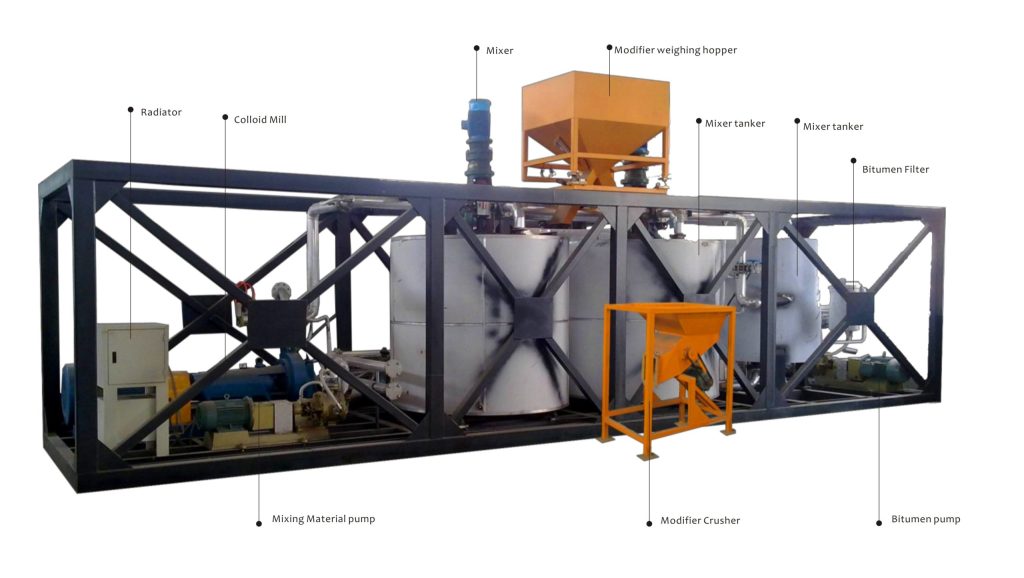

The polymer mixer plant is designed as a modular system for easy installation relocation and integration into existing asphalt or bitumen production lines.

Heating Unit

Thermal oil or electric heating system maintains stable temperature for the bitumen tank and mixing vessel

Mixing Vessel

Equipped with a vertical or horizontal agitator and high-shear mixer for complete polymer blending

Dosing System

Precision feeding pumps and flow meters regulate polymer additives filler and bitumen ratios

Control Unit

Centralized control panel with PLC HMI interface for process visualization data logging and alarm management

Safety System

Automatic overheat protection level sensors and emergency stop features ensure safe plant operation

Get Solutions For Your Project

ZOOMLINE offers economical, environmentally friendly, flexible and advanced solutions for customer’s project. Contact us now for more information about asphalt plant consultations.

Check our Solutions

PRODUCT COMPONENTS

COMPONENTS

Mixing Chamber

High-shear and low-shear mixing modes for different polymer types

Agitator System

Heavy-duty motorized agitator with adjustable speed for uniform mixing

Burner Assembly

Touchscreen interfacaDiesel or gas-fired burners with efficient combustion and low emissions e for real-time monitoring. Data logging, weight ticket printing and multi-format output. Integration with ERP, PLC and plant management software.

Heat Transfer Oil System

Provides consistent heating for all zones of the plant

Bitumen and Polymer Feed Pumps

Corrosion-resistant positive displacement pumps for precise dosing

Temperature Sensors

Digital thermocouples and PID controllers for continuous feedback and accuracy

Control Panel

PLC HMI-based control with recipe management and real-time parameter monitoring

Safety Valves and Relief Lines

Lines Built-in protection against pressure or thermal overload

Insulated Pipelines

To minimize heat loss and ensure stable temperature during transfer

PRODUCT Specifications

Technical

Specifications

The MAC MIX Polymer Mixer Plant is designed for the efficient preparation of polymer-modified bitumen used in high-performance road construction. The system provides stable temperature control, uniform mixing and precise dosing of polymer additives to ensure consistent quality. Built with a robust heating system, advanced mixing chamber and accurate control unit, the plant delivers excellent blending efficiency and energy savings. It supports various polymer materials and bitumen grades, offering reliable performance, easy operation and long-term durability in continuous production environments.

| Specification | 120-160 | 160-200 | 180-240 | 240-320 |

|---|---|---|---|---|

| Plant Capacity (t/h) | 120-160 | 160-200 | 180-240 | 240-320 |

| Filtering Area (m²) | 635 | 750 | 950 | 1200 |

| Processing Air Volume (m³/h) | 34560-69120 | 62000 | 53760-107520 | — |

| Collecting Efficiency | 99.8% | |||

| Exhaust Fan Power | 90 kW | 132 kW | 160 kW | 200 kW |

success cases

Projects

MAC MIX ARABIA polymer mixer plants are successfully operating across Saudi Arabia the UAE Qatar and Oman in major road infrastructure airport runway and highway resurfacing projects.

Our solutions help clients produce high-quality polymer modified bitumen (PMB) that meets international standards for durability and climate resilience.

Recent Project Highlights:

- Highway PMB production for the Riyadh Eastern Bypass

- Polymer blending plant integration with existing asphalt mixing systems

- Energy-efficient plant supply for a national road maintenance contractor

- On-site operator training and commissioning for municipal projects

Every project reflects our commitment to engineering excellence quality assurance and long-term performance.

faq

Frequently Asked Questions

It blends polymers with bitumen to enhance flexibility adhesion and resistance to deformation making the asphalt more durable and weather-resistant.

SBS EVA and PE-based polymers are commonly used depending on the performance target of the final bitumen product.

Yes our polymer mixer plants are modular and can be directly connected to asphalt mixing systems for continuous production.

Regular inspection of agitator blades pump seals and heating coils is recommended to maintain consistent performance and extend plant life.

Pit-type, pitless, modular steel deck and concrete deck options.

CONTACT US

Get Free

Solution

For customized polymer mixer plant design and quotations contact our sales team:

📧 info@macmixarabia.com

📞 +966 555 277 458

Provide details on your bitumen type polymer additive and production capacity to receive a complete technical proposal and price estimate.

We Will contact You With in 24 Hours

Fill in your contact information

Within 24 hours

Engineers get in touch with you

Fill in your contact information

PRODUCTS

Related

Products

Asphalt Plant

Truck Weighing Scale

Bag House Filter