The MAC MIX Asphalt Batching Plant is an advanced solution designed to meet the modern standards of road construction and infrastructure development. Every component is engineered for accuracy, durability and efficiency to deliver high-quality asphalt for projects of any scale. From aggregate feeding to hot mix discharge every process is optimized for reliability and consistent performance.

MAC MIX plants are built for contractors and developers who demand productivity and long-term value. The system combines intelligent automation with precise measurement to ensure uniformity and energy savings. Designed for continuous operation and minimal downtime the Asphalt Batching Plant provides a cost-effective approach to premium asphalt production.

PRODUCT ADVANTAGES

Advantages &

Features

Precision Aggregate Handling

Frequency-controlled feeding belts ensure accurate aggregate proportioning for consistent asphalt quality.

Advanced Dust & Emission Control

Dual-stage dust collection system keeps emissions below 30 mg/Nm³, meeting strict environmental standards in KSA.

Smart Temperature & Safety Management

Temperature monitoring and burner protection enhance safety, plant reliability and fuel efficiency.

Efficient & Flexible Fuel System

Optimized drum and burner design reduce fuel consumption.

Smart PLC Automation

Fully automated PLC control system for easy operation and monitoring.

Quick-Setup Modular Design

Modular construction allows quick setup and relocation.

Wear-Resistant Build

Durable wear-resistant materials extend service life.

Support & Training

24/7 customer support and operator training.

PRODUCT Introducion

Asphalt Plant

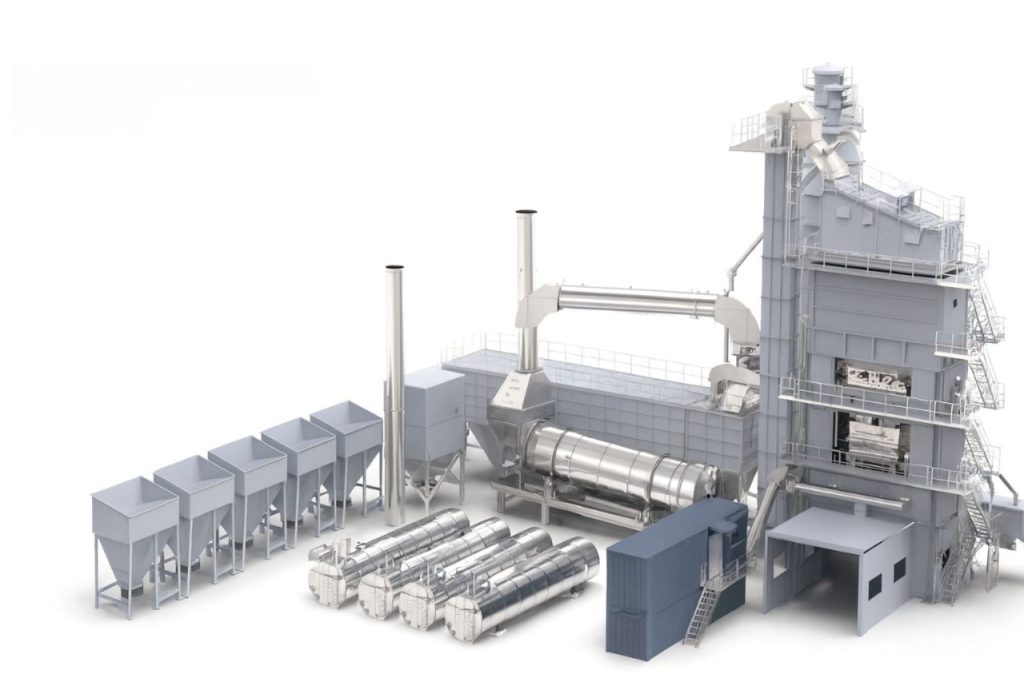

The MAC MIX Asphalt Plant has a modular structure that simplifies transport and installation. Each section of the plant is manufactured for maximum stability and minimal vibration. The framework ensures seamless coordination between systems so every process from cold feeding to mixing performs efficiently.

The structural design features heavy-duty steel frames, corrosion-resistant coatings and well-planned walkways for safety and maintenance. The modular layout enables flexible configuration according to the project size or site condition. This structure is what allows MAC MIX plants to perform reliably in demanding environments and deliver consistent production throughout their service life.

- 01 Mobile Cold Aggregate Feeding System

- 02 Mobile Drying Drum with Burner

- 03 Mobile Mixing Tower

- 04 Mobile Dust Collector

- 05 Mobile Control Room

- 06 Diesel Storage Tank

- 07 Mobile Bitumen Storage Tank

- 08 Filler Silo

- 09 Recycled Filler Silo

Get Solutions For Your Project

ZOOMLINE offers economical, environmentally friendly, flexible and advanced solutions for customer’s project. Contact us now for more information about asphalt plant consultations.

Check our Solutions

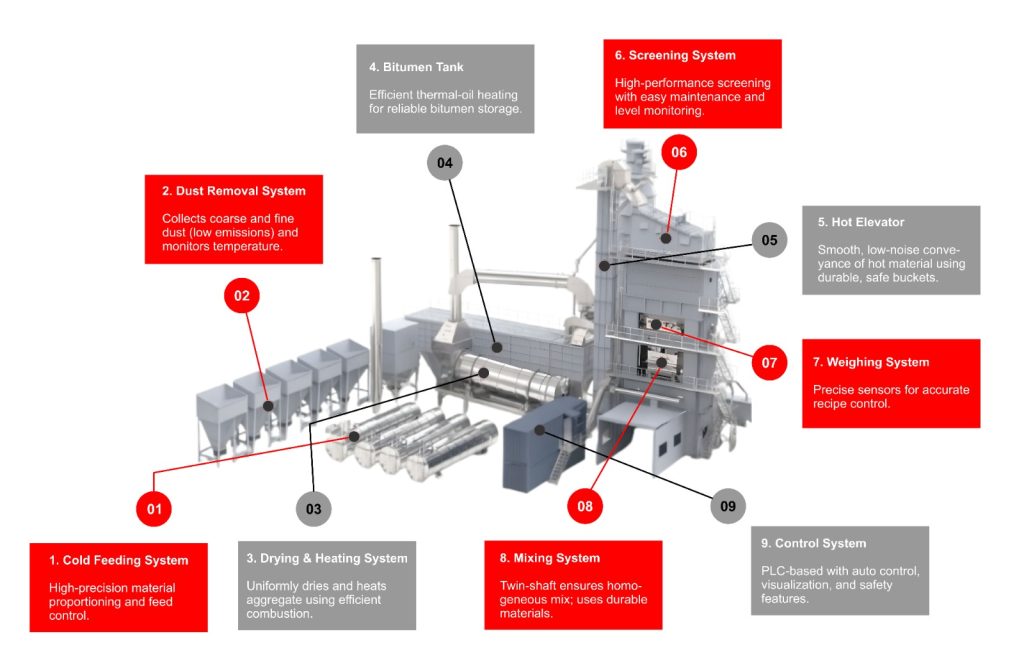

COMPONENTS FEATURES

Components

Features

Cold Feeding System

The cold feeding unit provides the first step in precision batching.

- Frequency-controlled belts ensure exact material proportions.

- Vibrators prevent material blockage and promote steady flow.

- Warning devices stop the belts if they run without load.

- High-precision gear reducers enhance transmission efficiency.

- Wedge-shaped discharge outlets minimize belt wear and improve longevity.

Dust Removal System

The dust removal system meets environmental standards and maintains clean operation.

- Primary gravity dust collector removes coarse particles.

- Secondary pulse jet baghouse captures fine dust efficiently.

- Emissions remain under 30 mg/Nm³.

- Reclaimed filler is recycled into the asphalt mix.

- Built-in temperature control protects filters and burners from overheating.

Drying and Heating System

This system ensures thorough and even heating of aggregates.

- Optimized drum flights provide excellent heat distribution.

- Four-roller drum support keeps rotation smooth and balanced.

- Low-pressure atomizer achieves complete combustion with minimal waste.

- Burner offers a 10:1 turndown ratio for flexible control.

- Works with multiple fuel types for convenience and economy.

Bitumen Tank

The bitumen heating and storage unit guarantees temperature stability.

- Thermal-oil heating system is efficient and dependable.

- Fully insulated tanks prevent heat loss.

- Horizontal or vertical options are available for site flexibility.

- Compatible with thermal oil, natural gas or electric heating.

- Built for durability in all weather conditions.

Hot Elevator

The hot elevator provides smooth vertical transportation of heated aggregates.

- Double-chain bucket design operates quietly and efficiently.

- Backstop function ensures safe emergency shutdowns.

- Buckets made of wear-resistant steel increase lifespan.

Screening System

Accurate screening is vital for consistent asphalt mix quality.

- Dual-motor vibrating screen delivers precise separation.

- Easy mesh replacement allows fast maintenance.

- Level sensors automatically monitor silo filling.

- Overflow channels handle excess or rejected material.

Weighing System

Precision weighing guarantees correct mix proportions.

- Imported load cells offer high accuracy.

- Automatic correction and accumulation improve precision.

- Dual aggregate scales for large-capacity production.

- Bitumen scale uses frequency-controlled discharge for perfect recipes.

Mixing System

The twin-shaft mixer ensures a uniform and high-quality mixture.

- Blends materials evenly for consistent results.

- Liner plates and paddles coated with wear-resistant alloy.

- Quick-discharge gate enhances productivity.

- Low filling index improves efficiency and reduces energy use.

Control System

The plant’s brain ensures smooth coordination and easy management.

- PLC automation with automatic, semi-automatic and manual control.

- Intuitive interface for real-time visualization of all operations.

- Auto-save and recipe storage functions enhance convenience.

- Diagnostic and alarm systems prevent operational errors.

Service and Support

Comprehensive technical and operational assistance ensure long-term reliability.

- Modular assembly design simplifies relocation.

- On-site operator training ensures safety and efficiency.

- Remote troubleshooting and maintenance support available anytime.

PRODUCT Specification

Technical

Specification

| Model | MX2000 | MX2500 | MX3500 |

|---|---|---|---|

| Capacity (t/h) | 160 | 200 | 260 |

| Cold Feeding | |||

| Hopper Quantity (pcs) | 6 | 6 | 6 |

| Hopper Volume (m³/pc) | 12 | 12 | 14 |

| Loading Width (m) | 3.3 | 3.3 | 3.6 |

| Drying System | |||

| Drying Drum Ø×L (m) | 2.2×8 / 2×10 | 2.2×9 | 2.5×10 |

| Driving Power (kW) | 4×15 | 4×18.5 | 4×22 |

| Burner Capacity (MW) | 14 | 18 | 20 |

| Fuel | Diesel, Heavy Oil, Natural Gas | ||

| Mixing Tower | |||

| Screening Mode | Double Motor / Unbalanced Exciters | ||

| Screening Power (kW) | 2.2×2.9 / 2×11 | 2×5 / 2×11 | 2×7 / 2×15 |

| Sheet Quantity | 5/6 | ||

| Hot Bin Volume (t) | 35 | 50 | 70 |

| Mixing Capacity (kg/batch) | 2300 | 2800 | 3500 |

| Mixing Power (kW) | 2×37 | ||

| Filler Supply | |||

| Filler Silo Volume (m³) | 50 | 50 | 70 |

| Recycling Filler Silo Volume (m³) | 20 | 20 | 70 |

| Dust Collection System | |||

| Dust Collecting Mode | Gravity Dust Collection + Pulse Dust Collection | ||

| Filtering Area (m²) | 600 | 700 | 896 |

| Bitumen Supply | |||

| Bitumen Tank Quantity × Volume (m³) | 2×60 | 2×60 | 3×60 |

| Thermal-Oil Furnace (×10⁴ kcal/h) | 60 | 60 | 80 |

| Power | |||

| Power (kW) | 470 | 510 | 610 |

| Covering Area | |||

| Covering Area (m×m) | 45×35 | 45×35 | 55×35 |

| Options | |||

| Longitudinal Loading Silos (m³) | 10–80 | 10–80 | 40–120 |

| Lateral Loading Silo (m³) | 50 | 50 | 120 |

success cases

Asphalt Plant

Projects

MAC MIX Asphalt Batching Plants are operating successfully across Saudi Arabia, UAE, Oman, Egypt and Africa. They have been used in highways, airports and large-scale urban projects where precision and reliability are essential.

Every project highlights the plant’s ability to maintain continuous production with minimal downtime. Clients choose MAC MIX for its balance of advanced automation and practical operation which reduces production costs and ensures excellent asphalt quality.

Our engineers provide complete commissioning, on-site assistance and after-sales support to guarantee smooth operation. Each installation is a demonstration of our dedication to long-term performance and client satisfaction.

faq

Frequently Asked Questions

It combines intelligent automation with precision batching and eco-friendly dust control to deliver top-quality asphalt at reduced operating cost.

Yes, the PLC system allows multiple recipe storage with automatic calibration for each type.

Minimal maintenance is needed thanks to durable materials and simplified modular access points.

The insulated design and control system maintain consistent performance in extreme temperatures.

Depending on model size and site conditions, installation can be completed within 15 to 25 days by our engineering team.

CONTACT US

Inquiry

If you are looking to enhance your asphalt production capacity, the MAC MIX Asphalt Batching Plant is the ideal choice. It delivers precision, productivity and profitability for every project.

📧 info@macmixarabia.com | 📱 +966 55 527 7458

We Will contact You With in 24 Hours

Fill in your contact information

Within 24 hours

Engineers get in touch with you

Fill in your contact information

PRODUCTS

Related

Products

Concrete Plant

Crusher Plant

Truck Weighing Scale

Dust Collector