Introduction

Concrete is the backbone of modern infrastructure, playing a vital role in the construction of roads, bridges, residential complexes and commercial buildings. In Saudi Arabia, where large-scale infrastructure projects are continuously shaping the landscape, the demand for high-quality concrete is ever-growing. Concrete plants offer a reliable and efficient solution to meet this demand, ensuring precision, consistency and cost-effectiveness in construction.

With companies like MACMIX leading the industry, investing in concrete plant technology can significantly improve construction efficiency, sustainability and profitability. This blog explores the top benefits of concrete plants and their impact on the construction industry in Saudi Arabia.

Consistency in Quality and Strength

One of the major challenges in construction is ensuring consistent concrete quality throughout a project. Traditional on-site mixing methods often result in variations in composition, affecting the durability of the final structure.

How Concrete Plants Solve This Issue:

- Automated Batching: Ensures accurate proportions of cement, sand, aggregates and water.

- Quality Control Measures: Advanced testing techniques guarantee uniform compressive strength and workability.

- Reduced Human Error: The automated process minimizes inconsistencies, delivering high-strength concrete tailored to specific project needs.

For mega-projects in Saudi Arabia, such as Neom City and Red Sea Developments, concrete plants provide a scalable and reliable solution, ensuring structural integrity.

Increased Productivity & Efficiency

A concrete batching plant eliminates the time-consuming process of manual mixing, allowing construction companies to operate more efficiently. With automated processes, large volumes of concrete can be produced rapidly and continuously.

Key Productivity Advantages:

- Faster Project Completion: Continuous mixing reduces delays, accelerating project timelines.

- On-Demand Concrete Supply: Reduces downtime and ensures uninterrupted workflow.

- Automated Processes: Modern concrete plants use PLC-based automation to control operations, improving speed and precision.

Cost Savings & Reduced Waste

Cost-efficiency is a significant concern for construction companies and concrete plants provide a solution that minimizes material wastage and operational expenses.

How Concrete Plants Help Save Costs:

- Bulk Material Handling: Buying raw materials in bulk reduces procurement costs.

- Waste Reduction: Automated proportioning ensures the exact amount of materials is used, reducing waste.

- Labor Cost Reduction: Automation reduces the dependency on manual labor, lowering overall project costs.

By reducing unnecessary expenses, companies in Saudi Arabia can enhance profitability while maintaining high construction standards.

Environmental Sustainability & Green Construction

With Saudi Arabia’s commitment to Vision 2030, sustainable construction practices are becoming a priority. Concrete batching plants align with this vision by offering eco-friendly solutions.

Sustainability Features of Modern Concrete Plants:

- Recycled Aggregates: Many plants incorporate recycled materials, reducing environmental impact.

- Water Recycling Systems: Advanced plants recycle water used in the mixing process, conserving resources.

- Dust & Emission Control: Modern facilities have advanced dust collectors and filtration systems, minimizing air pollution.

- Energy-Efficient Operations: Smart batching systems optimize energy use, reducing carbon footprint.

With the Saudi Green Initiative promoting eco-friendly practices, construction companies can benefit from concrete plants that support sustainability.

Customization & Versatility in Concrete Production

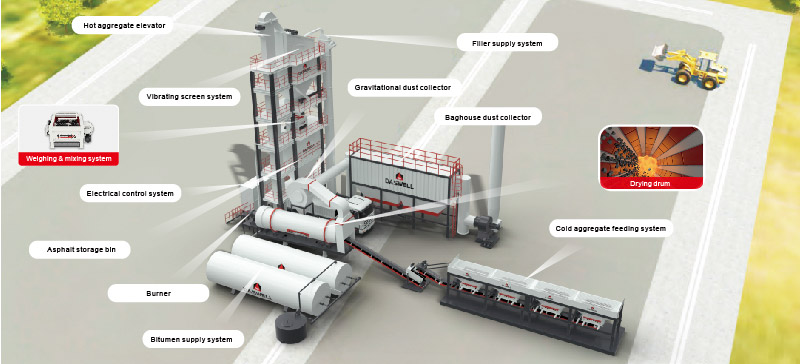

The Asphalt Production Process

Different construction projects require different types of concrete, depending on the structural load, climate conditions and specific engineering requirements.

Customization Features of Concrete Plants:

- Adjustable Mix Designs: Modify cement-to-aggregate ratios for specific project needs.

- Admixtures for Strength & Durability: Enhancements like fly ash, silica fume and superplasticizers improve workability and longevity.

- Colored Concrete & Special Finishes: Some plants allow for aesthetic customization, useful for decorative architecture.

For projects like airport runways, bridges and high-rise towers, having access to tailored concrete mixes ensures long-lasting performance.

Better Control Over Supply Chain & Logistics

Logistical delays can disrupt construction timelines, especially in large-scale projects. Having an on-site or nearby concrete plant provides better control over the concrete supply chain.

Supply Chain Advantages:

- Timely Deliveries: Ready-mix plants ensure concrete is delivered fresh and at the right temperature.

- Reduced Transportation Costs: Producing concrete closer to the site eliminates expensive transport expenses.

- Lower Risk of Material Shortages: Continuous production ensures a steady supply, preventing project disruptions.

For remote construction sites in Saudi Arabia’s vast desert regions, setting up a mobile concrete plant offers a strategic advantage.

Compliance with Saudi Arabia’s Construction Regulations

Saudi Arabia has strict regulations regarding building safety, material quality and sustainability. Concrete plants adhere to these regulations, ensuring compliance with industry standards.

Regulatory Benefits:

- ISO-Certified Production: Many concrete plants operate under ISO 9001 quality management systems.

- Government-Approved Mix Designs: Ensures adherence to Saudi Building Code (SBC).

- Safety Measures: Automated systems reduce risks of accidents and exposure to hazardous materials.

Compliance with these standards enhances project credibility and ensures regulatory approvals are obtained smoothly.

Conclusion: The Future of Concrete Plants

Concrete plants play a critical role in the construction sector, offering superior quality, efficiency and sustainability. As infrastructure projects continue to expand, investing in advanced concrete plants ensures cost savings, regulatory compliance and enhanced productivity.

For reliable and high-performance concrete solutions, MACMIX provides state-of-the-art concrete batching plants tailored to meet industry demands. Contact MAC MIX today for innovative and sustainable concrete production solutions!