Introduction

The Functionality of Polymer Mixer Plants

Key Steps in the Mixing Process:

1. Raw Material Feeding: Polymer resins, stabilizers, plasticizers and other additives are fed into the system through automated feeders.

2. Pre-Mixing: The materials undergo an initial blending phase to ensure uniform distribution.

3. Heating and Melting: The polymer is heated to an optimal temperature, allowing thorough mixing and proper chemical reactions.

4. Shear Mixing and Dispersion: High-shear mixers ensure even dispersion of additives, improving product consistency.

5. Cooling and Solidification: The final mixture is cooled and solidified into pellets, sheets, or liquid form for further processing.

6. Quality Control and Packaging: Samples are tested for consistency and the final product is packaged for shipment.

Types of Polymer Mixers

Polymer mixer plants utilize various types of mixers depending on the material properties and industry requirements. The primary types include:

- Batch Mixers

- Operate in controlled batches.

- Allow precise formulation adjustments.

- Ideal for specialty polymers and customized solutions.

- Continuous Mixers

- Ensure a consistent and uninterrupted mixing process.

- Suitable for large-scale production with uniform quality.

- Lower operational costs due to high efficiency.

- High-Speed Mixers

- Designed for rapid blending of polymers with additives.

- Utilize high-speed rotating blades to ensure even distribution.

- Commonly used in plastic and rubber industries.

- Twin-Screw Extruders

- Offer high shear and intense mixing capabilities.

- Enable precise temperature and pressure control.

- Used in advanced polymer compounding and masterbatch production.

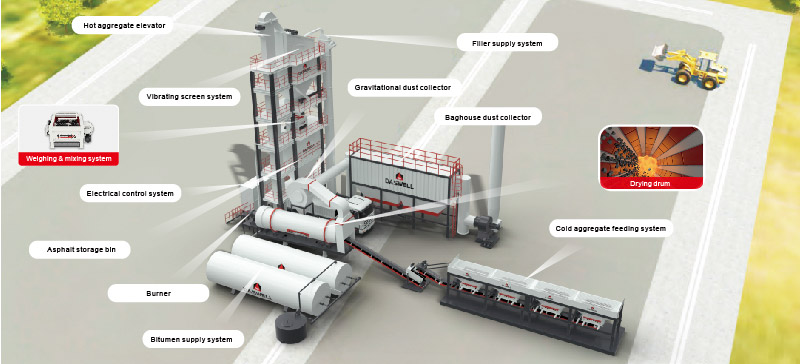

Components of a Polymer Mixer Plant

A fully functional polymer mixer plant consists of several essential components that work together to achieve efficient mixing and production. These include:

- Feeding System: Automated feeders precisely control raw material input to maintain formulation accuracy.

- Mixing Chamber: The core unit where polymer blending occurs, incorporating high-shear or low-shear mixing mechanisms.

- Heating and Cooling Units: Regulate temperatures to ensure optimal mixing and material stability.

- Extruder System: Used in specific processes to melt and shape polymer mixtures into usable forms.

- Control Panel: Features advanced automation, real-time monitoring and process optimization capabilities.

- Filtration and Degassing Units: Remove impurities and trapped air to improve polymer purity and consistency.

- Storage and Packaging Units: Ensure proper storage and transportation of finished polymer blends.

Uses of Polymer Mixer Plants Across Industries

Polymer mixing technology is widely utilized across multiple industries. Some key applications include:

- Plastics Manufacturing:

- Production of plastic granules, sheets and films.

- Development of composite materials for automotive and packaging industries.

- Rubber and Elastomers:

- Blending rubber compounds for tires, industrial seals and gaskets.

- Enhancing the mechanical properties of rubber-based materials.

- Adhesives and Sealants:

- Formulation of high-performance adhesives and bonding agents.

- Customization of sealants for construction and automotive sectors.

- Coatings and Paints:

- Manufacturing of specialty coatings for durability and aesthetic appeal.

- Mixing polymer emulsions to achieve consistent viscosity and texture.

- Medical and Pharmaceutical Industry:

- Development of biocompatible polymers for medical devices and drug delivery systems.

- Production of sterilizable polymer components for healthcare applications.

Advantages of Modern Polymer Mixer Plants

With advancements in automation and material science, modern polymer mixer plants offer several benefits:

- Enhanced Mixing Efficiency

- High-shear mixing ensures even dispersion of all components.

- Reduces material wastage and improves product consistency.

- Precise Process Control

- Advanced control systems enable real-time adjustments.

- Automated sensors monitor temperature, pressure and material flow.

- Energy Efficiency

- Modern plants are designed to minimize energy consumption.

- Optimized heating and cooling systems reduce operational costs.

- Scalability

- Plants can be customized for small-scale and large-scale production.

- Modular designs allow easy expansion of production capabilities.

- Environmental Sustainability

- Use of eco-friendly materials and energy-efficient technologies.

- Reduction of emissions and waste through advanced filtration systems.

Future Trends in Polymer Mixing Technology

As industries evolve, polymer mixing technology is expected to see significant advancements:

- Integration of AI and IoT:

- Smart sensors and AI-driven analytics for predictive maintenance and quality control.

- Sustainable Polymer Solutions:

- Development of biodegradable and recyclable polymers to reduce environmental impact.

- Advanced Automation and Robotics:

- Fully automated production lines to increase efficiency and reduce human intervention.

- Nanotechnology in Polymers:

- Enhanced material properties through nano-scale additives and modifications.

- Customized and On-Demand Production:

- 3D printing and digital manufacturing enabling rapid customization of polymer blends.

Conclusion

Polymer mixer plants are vital for multiple industries, providing efficient and high-quality blending of polymer materials. With advancements in automation, energy efficiency and sustainability, these plants continue to evolve, offering improved production capabilities and cost savings. Companies investing in modern polymer mixing technology can achieve higher efficiency, better product quality and enhanced competitiveness in the global market.

For expert solutions in polymer mixing and processing, MACMIX offers leading-edge technologies personalized to meet industrial needs. Contact us today to learn more about our innovative polymer mixer plant solutions!